Mahle Piston Rings Which Way Up

They must be lighter must have lower oil consumption and must be absolutely safe and reliable.

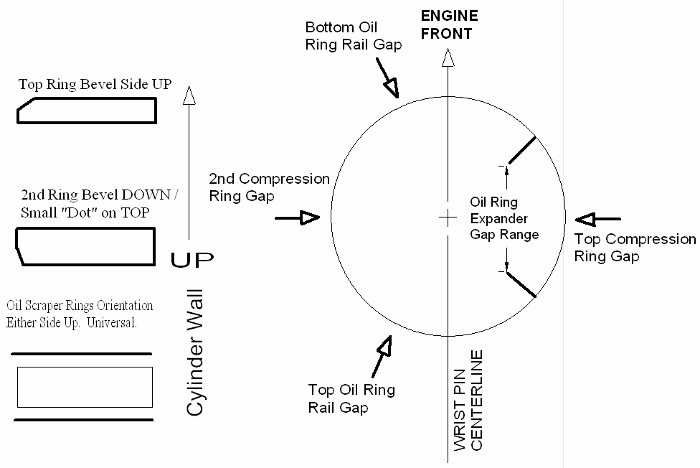

Mahle piston rings which way up. The manley s first and second rings have no bevels in the outer edge cylinder wall but has slight bevel in inner edges piston ring groove the second ring matte black cast has a dot marked so it is looking up. Pistons have to put up with extreme pressures as their working conditions have become significantly tougher in recent years. But what about the top ring. Barney145 view public profile.

In addition the second rings are reversed twist taper faced cast iron. It has no markings but has a bevel in the inner edge. Phosphate coating provides the grey appearance to the mahle piston. Mahle s grafal skirt coating reduces drag scuffing friction and cylinder bore wear.

Rings with a groove in the outside diameter and a pip mark or dot on the side must be installed with the groove toward the bottom of the piston and pip mark towards the top of the piston. Do not over expand the piston rings. Install rings labelled top with the lettering facing upwards towards the piston crown. Only use suitable ring pliers to fit the piston rings starting with the bottom ring.

It is a good idea after installing all rings on the pistons to recheck each ring on each piston for correct installation. At hastings manufacturing we want using our product to be as easy as possible starting with the second you open the box. For 1 5mm and 1 16 ring sets the top rings are positive twist ductile iron barrel faced plasma moly inlaid. Compensated ring grooves assure proper ring loading and oil control.

Should it be looking up or down. A steel napier second ring and industry leading cp 20 oil ring round out the package.