Milling 316 Stainless Steel Speeds And Feeds

Feed should be 0 5 x suggested value.

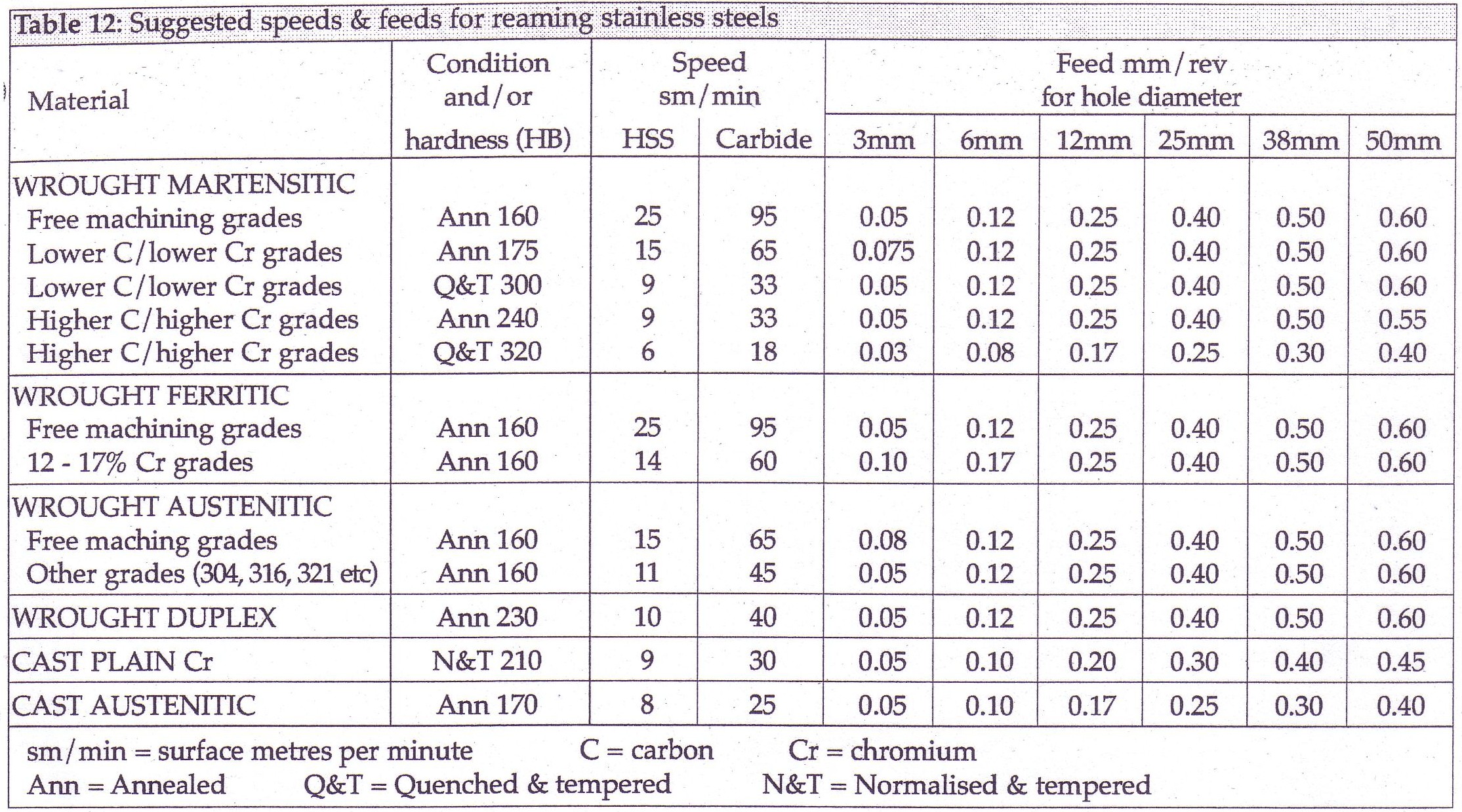

Milling 316 stainless steel speeds and feeds. Easy speeds and feeds only serves as a starting point and educational site. Reduce speed and feed by 30 when reamed hole size comes out too big. 304 ss carbide thread mill. Sfm and feed for ad between 0 25 to 0 5 of tool dia.

Sfm 0 8 lowest range value. Coated carbide endmills. Endmill diameter inches. Helical solutions offers the hev 5 end mill which is an.

For ad equal and above tool dia. Cutting feed ipr cutting feed ipr 0 007 0 010. Chipbreaker roughers would make an excellent choice in either 5 or 7 flute styles while standard 5 7 flute variable pitch end mills can also perform well in hem toolpaths. Endmill diameter inches.

Cutting feed ipr. We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end mills. Turning speeds are adjusted to the feed rate of the mini lathe 0 004 rev a depth of cut of 0 040 and a tool life of 180 minutes. Of teeth and the chip load per tooth to determine the feed rate in min use 002 005 as starting chip load per tooth.

The rules and principles of cutting speeds and rpm calculations apply to all of the operations being performed on drilling machines. An example of this would be reaming. Always use the speeds and feeds recommended from your tool manufacturer. Reduce speed and feed by 30 when reamed hole size comes out too big.

Sfm 0 8 x highest speed range. Click here to find the right drill size for you reamer. High efficiency milling can be a very effective machining technique in stainless steels if the correct tools are selected. Reaming is done at half the speed and twice the feed as drilling.

This rule still applies on the drill press as it does on the milling machine or the lathe. Cutting feed ipr 0 001 0 003.